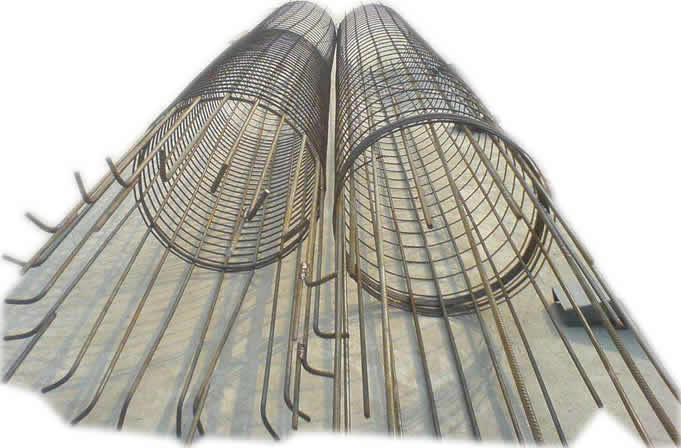

Steel Pile Reinforcement Cages, Pads and Columns

Quick View

We supply welded rabar cages and welding machines. Reinforcing steel bar cages are circular mesh cages used in the pre-casting production of pits, covers and tunnels. Especailly used in oil industry for sub marine construction of oil conveying pipes projects. The pre-welded rebar cages are supplied in piles, pads, columns and other shapes to meet specific uses. We supply pile cages with a variety of cage pitch, hoop diameter, wire numbers and length.

Carbon Steel Rebar Welded Cages

Specially used for strengthening concrete. It is made by welding with black steel rods into a cage-shaped steel banding mounted skeleton. Generally used in the pile for reinforcement or to strengthen tendons of location bar, etc.

Spiral rebar cage is used to ensure the transverse force of the pile. Its density has a crucial role to prevent the pile case from cracking.

Black iron rebar cages designed using rebar with square rebar links spaced at 200mm centres, for underground sea projects.

Two Ways to connect the short pile cages together:

A, Combine the main rebar first and then the pile cage, that is to say, butt weld the rebar of 9m length together to 9-27 meters and then use the pilemaster to longer pile cage.

B, Combine the pile cage and then the main rebar, first make the pile cage of 9m or 12m of standard. And then weld the short pile cages to longer pile cages.

How to install the inner reinforcing bar and double rebar:

To get the double rebar pile cages to improve work efficiency, normally we suggest welding the second bar after the pile cage is formed.

And for the inner reinforcing bar, we supply the rebar bending machine to reinforcing the stirrup. Compare to weld manually, the difference is the rebar ends do not bond together, hence easier to install.

Non Galvanized Black Main Rebar and Reinforing Cages

We Supply Steel Rebar Cage Welding Machine for Export

Parameters:

| Diameter of welded frame | ø250-ø1200 |

| Length of welded reinforcement cage | 4M-15M |

| Number of longitudinal reinforcement steel bar | 6, 7, 10 , 12, 14, etc |

| Diameter of longitudinal reinforcement rebar | ø7.1, ø9.0, ø10.7, ø12.6MM |

| Diameter of hoop reinforcement | ø4- ø6 |

| Cage pitch | 0-100mm |

| Driving power | 8.4KW-15.2KW |

| Welding power | 200KVA-300KVA |

| Controller | NC controller |

Each parts details:

Automatic concrete pile rebar cage welding machine is a special-purpose welder used to- produce the high-strength concrete pipe pile reinforcement cages. The welder is widely-appliedto reinforcement cage welding by self-stressing and prestressing pretensioning-method and post-tensioning method.

Working principle:

The system consists of 4 parts of driven systems, inclusive Master plate of Rotation, Plate of push reinforcing steel , expansion diameter part, and welding machine. The 4 parts are drived by independent electrical motor. The Full variable frequency control ensures that the span of the latitude steel and the angle of the spigot won't not change along with the welding speed. Adjustment the ratio of motor speed can change the span of latitude steel, and angel of spigot. This machine can weld different diameter cages via adjustment of location and position of the master plate and welder.

Cage welding machine is a special-purpose welder used to produce the high-strength concrete pipe pile reinforcement cages. The welder is widely applied to reinforcement cage welding by self-stressing and prestressing pretensioning method and post-tensioning method.

- -Large diameter of weldable main reinforcement, long frame, small torsion and good integral performance;

- -Small weld strength loss;

- -Adjustable cage pitch and quick forming;

- -High-speed and stable operation and high efficiency;

- -Variable frequency control and high stability and reliability;

- -Rational structure and easy and convenient operation and maintenance.

Features:

- -Automatic PLC control, Man-machine interface, Touch screen.

- -Variable Frequency Speed control and inverter;

- -Pneumatic clamping system, Gear wheel chain on the main plate;

- -Transformer and electrode water cooling system.

- -It makes up of four systems:The Main plate; Pushing Plate; Diameter changing; and Cooper welder,they are working

- driven by the separate motor. The Variable Frequency Ratio speed control system will promise the spiral pitch

Considering Grid Sheets for Concrete Precasting? Click here. Welcome to contact us with your specific requirements.