Gabions, Hot-dipped galvanized, Galfan or PVC coated Finish

Quick View

Collapsible gabions can be fabricated from woven wire mesh hexagonal netting or HDG welded mesh sheets. Wire mesh gabions finishes can be hot-dipped galvanized, galvanized aluminum alloy Galfan or PVC coated coating. This metal mesh containers are supplied in a range of wire and mesh sizes, uniformly partitioned into internal cells, filled with stone at the project to form flexible, permeable, monolithic structures. Gabions or stone containers are widely used as retaining walls, sea wall, channel linings, revetments, and weirs for river bank protection erosion control projects.

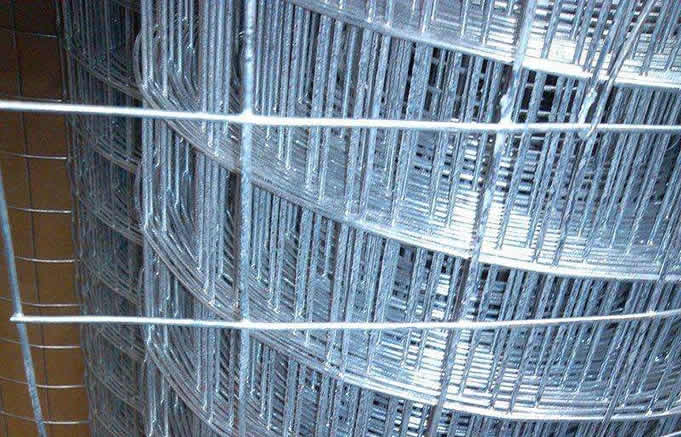

Welded Mesh Gabions

Gabions made of welded wire fabrics offer much strength compared with woven mesh gabions.

Materials: Galvanized steel with zinc coating (cold drawn high tensile steel zinc coated);

Plastic coated steel;

Galfan of zinc aluminum alloy.

1mx0.5mx0.5m heavy duty galvanized gabion box, of collapsible, foldable mesh panels.

Retaining Walls of Square Hole Welded Mesh 75x75 mm

Popular Material Type: Galfan Gabbions.Galfan gabion gets its name from its wire material: a kind of heavy Galfan (zinc-5% aluminum alloy) soft tempered steel . Compared with traditional galvanized steel gabions with pure zinc coating, Galfan gabion features a heavy zinc – aluminum coating layer which enables an excellent corrosion resistance. The corrosion resistance of Galfan gabion doubles that of traditional pure zinc plating.

The steel wire used in the manufacturing of the gabion is heavily galfan( [Zn-5 Al-MM] alloy) coated soft temper steel. A PVC coating is then applied to provide additional protection for use in polluted, contaminated or aggressive environments: in salt, fresh water, acid soil or wherever the risk of corrosion is present. The PVC coating has a nominal thickness of 0.50 mm to 1.00mm. Galfan plus PVC coating gabions, simplified as Galfan gabions, are strong and durable for long term uses.

This type of gabions are made of welded (not woven ) square mesh (usually 75x75mm hole size) with equal opening horizontally and vertically. Popular specifications with wire diameter, mesh hole, Galfan coating minimum requirements per square meter, as below:

1.0 x 1.0 x 0.5m – wire diameter - 3.0mm., mesh size 75 x 75 mm., coating Galfan [ZnAl] – min. 235g/m2

2.0 x 10 x 0.5m – wire diameter - 3.0mm., mesh size 75 x 75 mm., coating Galfan[ZnAl] - min 235g/m2

2.0 x 1.0 x 1.0m – wire diameter - 3.0mm., mesh size 75 x 75 mm., coating Galfan[ZnAl] - min 235g/m2

1.0 x 1.0 x 05m – wire diameter - 4.5mm., mesh size 75 x 75 mm., coating Galfan[ZnAl] - min 235g/m2

2.0 x 1.0 x 0.5m – wire diameter - 4.5mm., mesh size 75 x 75 mm., coating Galfan[ZnAl] - min 235g/m2

2.0 x 1.0 x 1.0m – wire diameter - 4.5mm., mesh size 75 x 75 mm., coating Galfan[ZnAl] - min 235g/m2

Installation and Fixing

In common with all gabions during installation, all welded units need internal bracing wires to be overfilled to allow for settlement of the granular rock fill.

Installation

Empty gabion baskets shall be assembled individually and placed on the approved surface to the lines and grades as shown or as directed, with the position of all creases and that the tops of all sides are level. All gabion baskets shall be properly staggered horizontally and vertically as shown in the construction drawings. Finished gabion structures shall have no gaps along the perimeter of the contact surfaces between adjoining units. All adjoining empty gabion units shall be connected along the perimeter of their contact surfaces in order to obtain a monolithic structure. All lacing wire terminals shall be securely fastened. All joining shall be made through selvedge-selvedge or selvedge-edge wire connection; mesh-mesh wire connection is prohibited except in the case where baskets are offset or stacked and selvedge-mesh or mesh-mesh wire connection would be necessary. As a minimum, a fastener shall be installed at each mesh opening at the location where mesh wire meets selvedge or edge wire.

a.The initial line of gabion basket units shall be placed on the prepared filter layer surface and adjoining empty baskets set to line and grade, and common sides with adjacent units thoroughly laced or fastened. They shall be placed in a manner to remove any kinks or bends in the mesh and to uniform alignment. The basket units then shall be partially filled to provide anchorage against deformation and displacement during the filling operation. The stone shall be placed in the units as specified or directed by the manufacturer.

b.Deformation and bulging of the gabion units, especially on the wall face, shall be corrected prior to additional stone filling. Care shall be taken, when placing the stone by hand or machine, to assure that the PVC coating on the gabions will not be damaged if PVC is utilized. All stone on the exposed face shall be hand placed to ensure a neat compact appearance.

c.Gabions shall be uniformly overfilled by about 1-3 inches to account for future structural settlements and for additional layers. Gabions can be filled by any kind of earth filling equipment. The maximum height from which the stones may be dropped into the baskets shall be 3'.

Stone Placement

When excavation and foundation preparation are completed, the pre-assembled gabions shall be placed in their proper location according to the plans provided.

Gabions shall then be connected together and aligned prior to filling with stone. The stone fill shall have a gradation as listed or specified within the contract specifications or as listed within this specification. The stone fill shall be placed into the gabion units in 1' lifts. Cells shall be filled to a depth not exceeding 1' at a time. The fill layer should never be more than 1' higher then any adjoining cell. Connecting wires shall be installed from the front to back and side to side of the individual cells at each 1' vertical interval for gabions with a depth of 3'. The voids shall be minimized by using well graded stone fill and by hand placement of the facing in order to achieve a dense, compact stone fill. All corners shall be securely connected to the adjoining basket of the same layer before filing the units. When more than one layer of gabions is required, in order for the individual units to become incorporated into one continuous structure, the next layer of gabions shall be connected to the layer underneath after this layer has been securely closed. Gabions shall be uniformly overfilled by about 1-2 inches to account for structural settlement.

Applications

Retaining walls, earth retaining structures;

Protection of highways, crossing works, rockfall protection;

Slope & soil protection;

Protection of culverts and bridges;

Hydraulic structures, water recharge & flood control dams;

Environmental application;

Marine works;

Channel, canal lining, river training works, irrigation & drainage works;

Protection of islands, coastal embankment, shore protection, harbor / marine works;

High security fencing;

Erosion & scour protection, oil pipeline protection.

Gabions We Offer

Rock Wall Netting Gabion Cells Forming Wall Structure

Woven wire mesh gabion baskets: 60x80 twisted hexagonal holes

Double twisted wire hex netting mattress 100x120mm x 2.0mm.

Galfan wire gabions suitable for sea water flood control, green powder coating finished.

Galvanized and PVC Coated 80X100mm Twisted Mesh Gabions in 2m x 1m x 1m

Hot Dip Galvanised Mesh Welded for Gabions Fabricating

Welcome to contact us with your specific requirements.