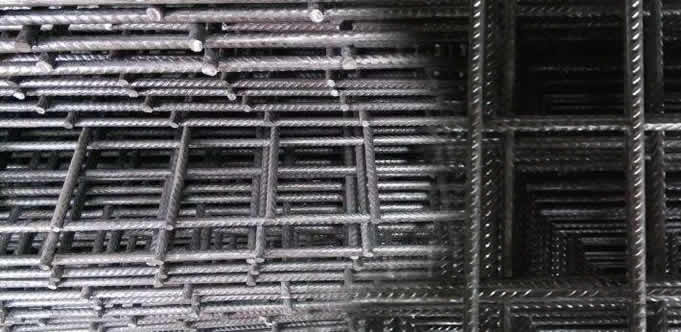

Galvanised and Black Steel Wire Welded Netting for Concrete Construction

Quick View

We supply heavy type welded sheets of steel wire or ribbed bars, used as structural building materials. Finishes can be non-galvanised black steel, electro galvanized and hot dipped galvanized. Rebar welded panels are prefabricated reinforcement fabrics for precast concrete elements construction, particularly suitable for flat slab construction and concrete surface beds. Applied in projects of buildings, airports, banks, bridges and road pavement. The welded steel bar panels are designed to improve the earthquake resistance and anticracking property of the concrete construction. Also known as construction mesh, reinforcing mesh.

Steel Bar Mesh Panels according to the raw materials can be divided into: cold-rolled ribbed bar net, cold-drawn round steel bar mesh, hot-rolled ribbed bar mesh. The cold-rolled nets are the most widely used materials which can significantly improve the quality of reinforcement engineering. Supplied in a variety of steel grade, diameter, length and spacing. The welded rebar reinforcing mesh can be flat or other fabricated forms.

Materials

Material Processing: Cold-rolled or hot rolled, cold drawn material.

Rebar diameter:4-12mm.

Sheet Length: no more than 12m.

Width: no more than 2.5m.

Mesh opening width:100mm,150mm, 200mm.

Mesh opening length:100mm,150mm, 200mm.

Surface Treatment: Self colored black steel, bright electro galvanized or hot-dipped galvanized.

Materials: Low carbon steel wire, mild steel wire, stainless steel wire and steel rod, steel bars

Application

Using of steel bar welded mesh for reinforcement mat materials saves considerable cost. This is the most economic metal structure applied to concrete elements.

Detail applications include:

Suspended floor slabs, concrete walls, culverts / drains and composite brick / concrete;

In construction of housing floor, roof wall, terrace, concrete pavement;

In projects of road pavement, deck paving, airport runway, tunnel lining, concrete pipes, piles of industry and civilian;

Retaining and shear walls;

Beams and columns construction;

Concrete paving overlays;

Precast concrete elements;

Buildings project;

Swimming pool and gunite construction.

Varieties According to Materials and Finishes

Non Galvanized Reinforcing Mesh

High Tensile Strength Welded Mesh Grid with Rectangular Opening

The black steel bar welded fabric is manufactured under strict quality controls with all standards conforming to SANS 1024:2006 standard specifications and tolerances and carries the certification mark.

Black mesh mats can be scheduled simply by reference to the fabric type, sheet dimensions and bending shape codes. (The reference is the nominal mass of the fabric in kg/m2 x 100).

The cold-rolled deformed wire or steel bar used in forming fabric has a characteristic strength (0.2% proof stress) of a minimum of 485MPa compared to 450MPa for high tensile rebar. The black iron weld mesh mat may be used at higher stresses than high tensile rebar resulting in a material saving of up to 8%.

Galv. Carbon Steel Reinforcing Mesh Panels

This welded mesh has normally rectangular opening with closer horizontal wires than the square opening welded wire mesh for general utilities. It is made with low carbon steel wire undergoing a cold rolling and straightening process, and then arranged vertically in proper spacing at line wires and at cross wires, and joint together by electric resistance spot-welding (also directly welded with hot-rolled wire rods ), turning into steel fabric mesh sheets.

4 inch x 4 inch rebar welded reinforcing mesh fabric

Structures

Welded Steel Rod for Construction consists of pieces of wire or rebar welded together to form a grid pattern. The size of the grid pattern is typically 4-inch-by-4-inch up to 8-inch-by-8-inch. This type of reinforcement is used to minimize shrinkage cracking in the surface of the concrete.

Hot Rolled Reinforcing Mesh Panels

Hot Rolled Weld Sheet with firm welding spots and uniform wire spacing.

Hot rolled rod is the popular material for making of welded wire reinforcing fabrics. It can be made with pre galvanized wire then weld together, or hot dipped with zinc plating after weld processing. The low cost and strong and flexible structure make it an ideal structural building materials, with the feature of strengthening and reinforcing.

Steel mesh sheets or rolls for a quick and simple site installation process.

Benefits of Using Reinforcing Rebar Mesh

It will considerably reduces construction time;

Improve construction speed;

Reinforced concrete cracking resistance;

Good overall economic efficiency.

1.Quality Assured

Reinforcing weld mesh is made by fully automatic and intelligentized production line under strict quality control. The Mesh grid, reinforcing mesh specification and quality are all strictly controlled. The mesh panel has high intensity, good flexibility, accurate spaces and welding joint. The project quality improves a lot.

2. Improving the function of earthquake proof and anticracking

The network of the reinforcing mesh combines with concrete. The pressure will spread evenly. This will obviously improve the function of earthquake proof and anticracking of the reinforcing mesh. According to some tests, reinforcing mesh built on the roads will reduce at least 75% of the crack happening.

3.Saving the reinforcing bar

The common used reinforcing bar strength is 210N/mm. While the design strength of the reinforcing mesh is 360N/mm(pingfang).Using reinforcing mesh will save 30% of the quantity of the reinforcing bar. Besides, there is no loss because we need to process after carrying the reinforcing mesh to the construction site.

4.Speed up the construction

Using concrete reinforcing mesh will speed up the construction. We can pour the concrete after laying the reinforcing mesh. So we omit some complex segments. By using reinforcing mesh will save time and shorten the construction period.

Choose Right Specifications to Import to Your Market

How is the Reinforcing Panel Used in Concrete Construction

Looking for machines to set up a plant? Welcome to contact us with your specific requirements.